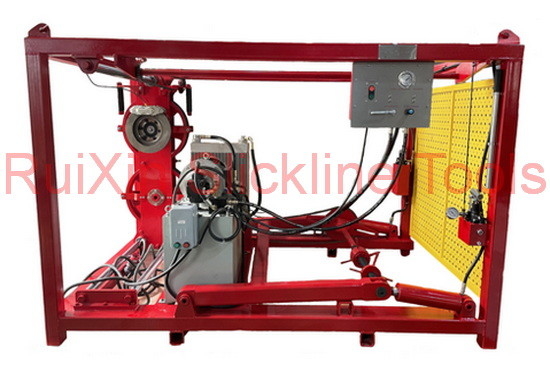

Wireline Hydraulic Spooler Spooling Unit

Ⅰ. Introduction

The working principle of the equipment is that the hydraulic system drives the hydraulic motor, the hydraulic motor transmits power to the chuck through the chain, the chuck drives the drum to rotate, and the cable (or wire) is wound on the drum at a uniform speed. This equipment is made of steel frame structure and controlled by panel centralized operation. It has the characteristics of high strength

Ⅱ. Specification parameter

Applicable cable specification: 0.092 "-5/16"

Motor power: 7.5KW

Total power input: AC380V/50HZ

Solenoid valve power input: DC24V

Dimension of rope guide wheel: 20 "

Maximum cable tension: 3000 pounds

Ⅲ. Note:

1.During the operation of this equipment, for your safety, do not enter any part of your body into the equipment!

2.When the oil temperature in the oil tank is close to 80℃, please stop to cool down.

3.When the drum is not raised, it is forbidden to start the hydraulic motor.

IV.Maintenance

After using the equipment, the reversing valve knob must be placed in the middle position, and the speed regulating valve and two stop valves must be placed in the open position at the same time.

The hydraulic oil pipe is a vulnerable part. If any damage or leakage of the oil pipe is found, please stop using it immediately and replace the qualified oil pipe. After replacement, debugging is normal and can be reused without leakage;

After using this equipment, the oil cylinder shall be minimized to prevent leakage caused by long-term pressure keeping.

When it is found that the oil level of the oil tank is lower than the above position, the hydraulic oil shall be replenished in time.

◆About Baoji RuiXin Slickline Tools

Baoji Ruixin Energy Equipment Co., Ltd. was established in 2012. It is an IS0: 9001-2015 and API Q1 system certified technology research and development organization specializing in the design and manufacture of steel wire, cable and coiled tubing tools. With strong new product research and development capabilities, it has obtained 12 national utility model patent certificates and 1 invention patent certificate. Undertook two prefecture-level and provincial-level scientific research projects. Our products include wireline wireline wellhead blowout prevention equipment, wireline downhole tools and coiled tubing downhole tools. At present, we have provided professional equipment and technical support to more than 50 oilfield service companies in various regions at home and abroad.

◆Strict quality control system

Steel wire working tools are certified by API, and all manufacturing are strictly in accordance with API system, including quality control management, environmental management and occupational health and safety management. For each wire working tool and each part, we have achieved traceability from raw materials, production process to product shipment.

◆Hard work, after-sales service

On-site technical guidance exchanges with each other. Our sales and technical personnel communicated well with front-line engineers and technical experts on the job site, and solved technical problems such as material selection, sealing structure optimization, and accident handling in complex environments. And carried out many technical exchanges and friendly cooperation. We have done a good job of product after-sales service for customers, and we provide customers with more satisfactory services. We would like to thank more and more customers for their support and trust. In the future, we will do better.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!